2024-04-26

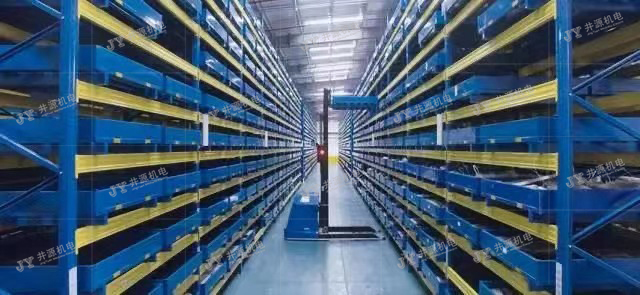

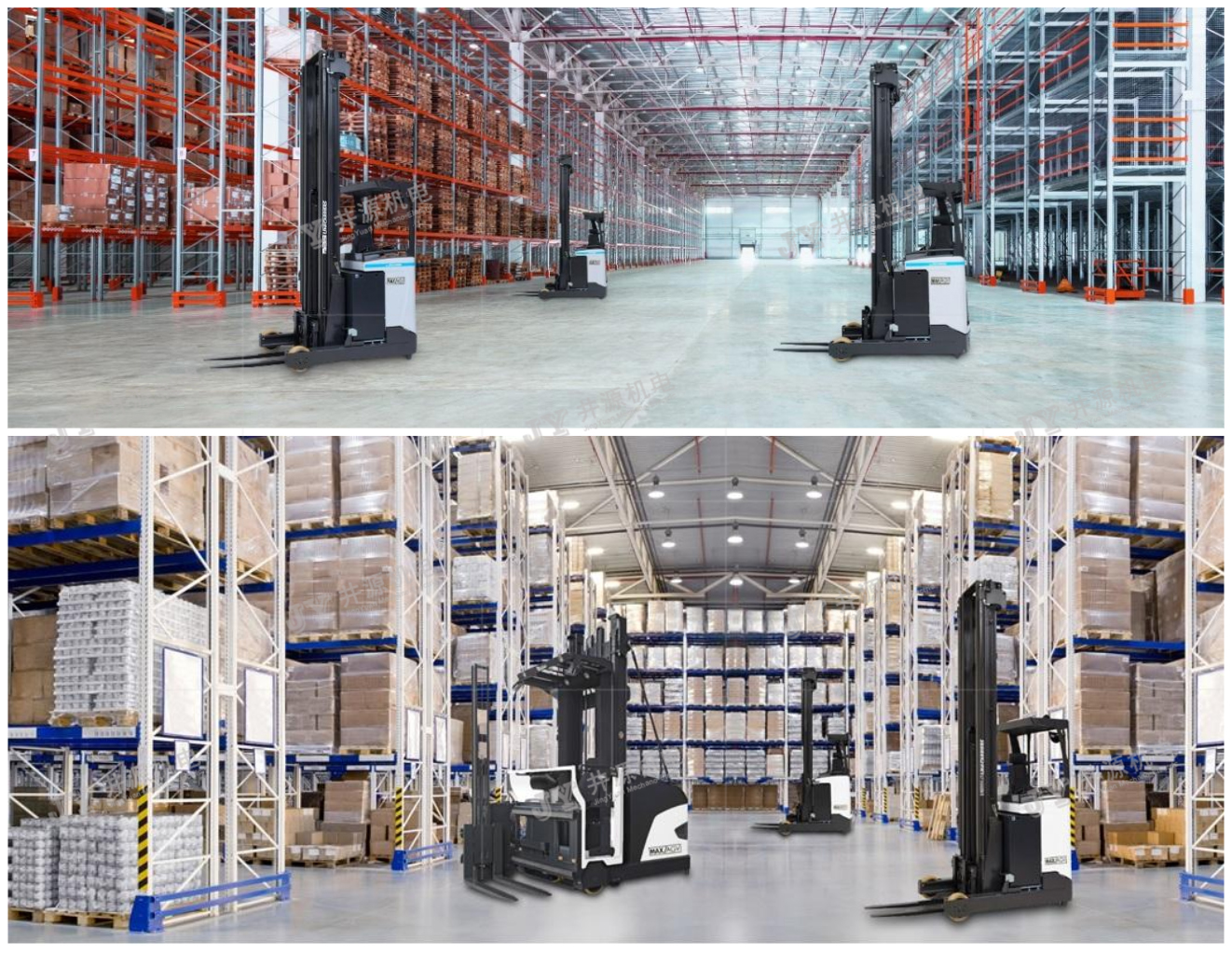

In order to ensure complete management of the mold warehouse, accurate and timely data accounting, prevent damage to materials during the warehouse management process, and improve warehouse capacity, a domestic tire factory adopts the Jingyuan Electromechanical High Lift Forklift AGV system to achieve automatic mold in and out storage and warehouse management, making production more automated, informationized, and intelligent. While reducing labor intensity of workers, it also improves warehouse capacity and logistics efficiency.

This project adopts laser guided high-altitude forklift AGV, with a load capacity of up to 1.5T, a lifting height of 6.5m, and a minimum operating channel width of 3500mm. AGV can accurately deliver mold pallets to designated storage locations through the information instructions provided by the MES system, complete the transportation work of inbound and outbound, and feedback the results to the MES system, thereby achieving production automation, informatization, and intelligence.