A well-known domestic household appliance brand has built an advanced intelligent factory in the production base of a commercial dryer project to improve the overall production efficiency, achieving automated and intelligent manufacturing of the entire factory.

Project Description

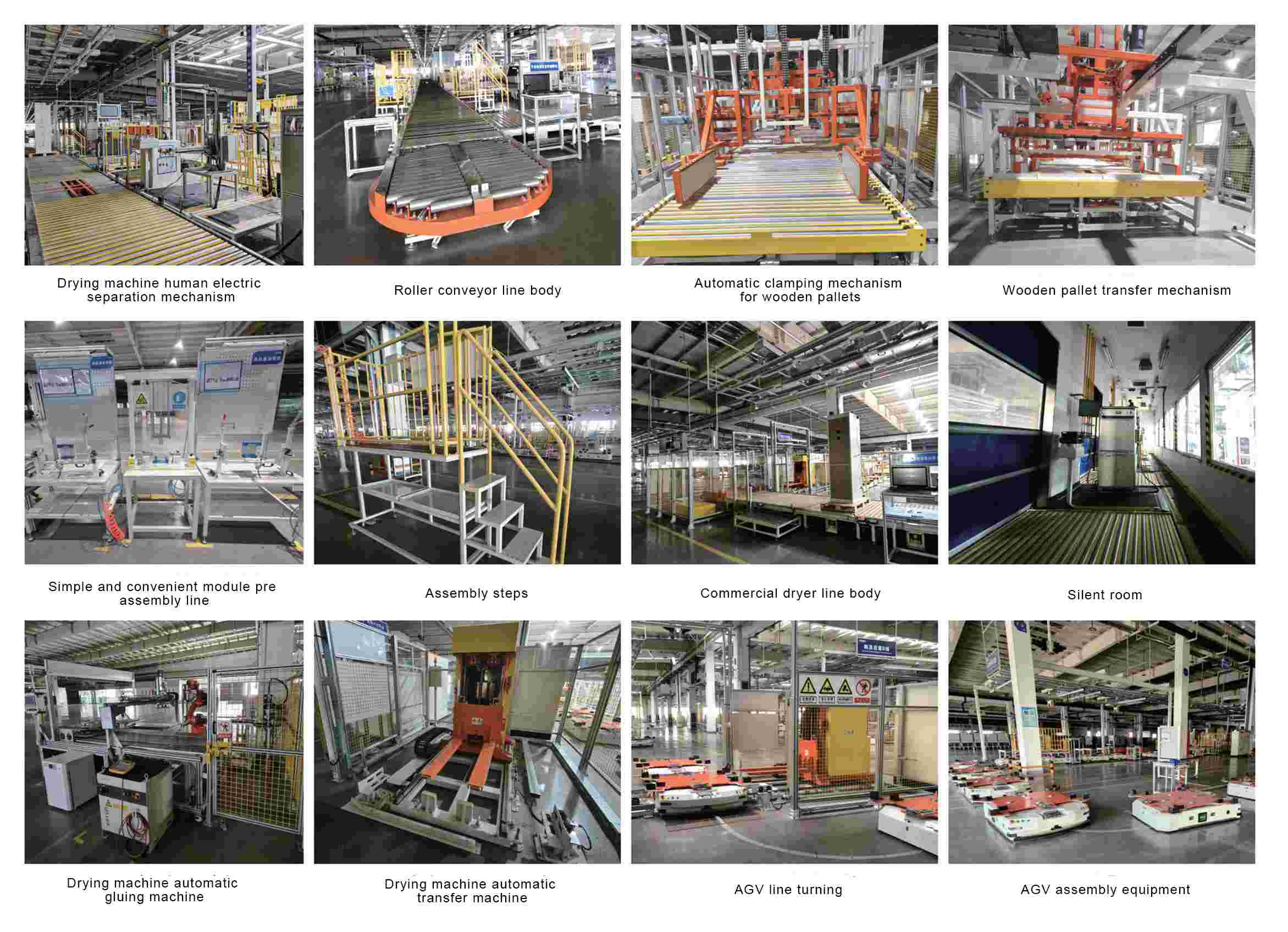

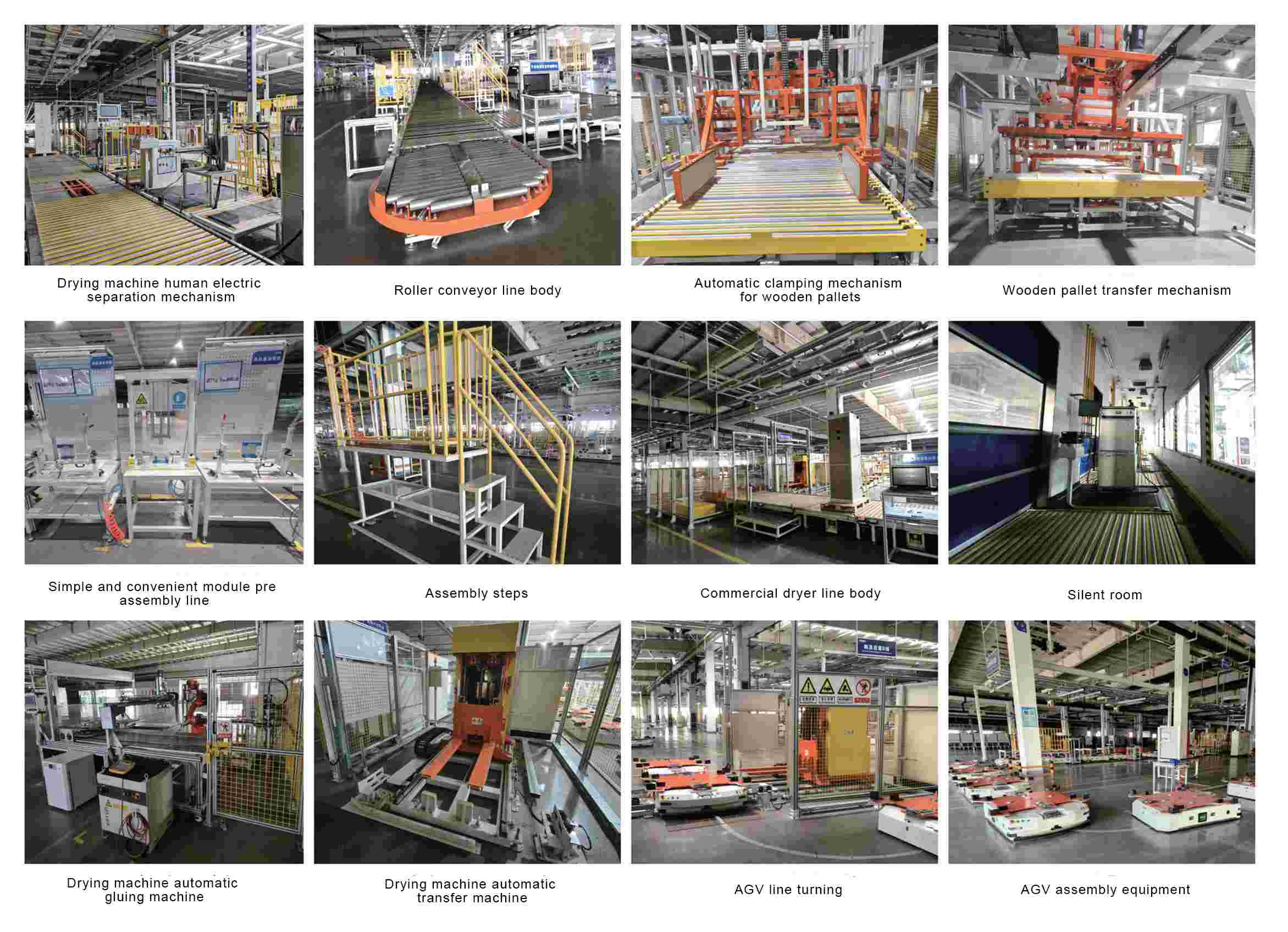

In this project, the commercial dryer intelligent final assembly production line is mainly used for the intelligent assembly production of multiple models of dryers. The plan is to use intelligent AGV as the driving force to complete the flexible, information-based, and intelligent production of different models of dryers, and to achieve automated transportation of production processes such as final assembly, testing, cleaning, and packaging. The assembly line package includes: final assembly, inspection, cleaning, packaging and transportation, intelligent balancing crane, simple and convenient module pre assembly line, testing equipment, auxiliary equipment, tooling tools, AGV assembly equipment, etc.

Equipment parameters

Overall production capacity: 216000 units/year

Production rhythm: 30JPH

Equipment comprehensive efficiency: ≥ 98%

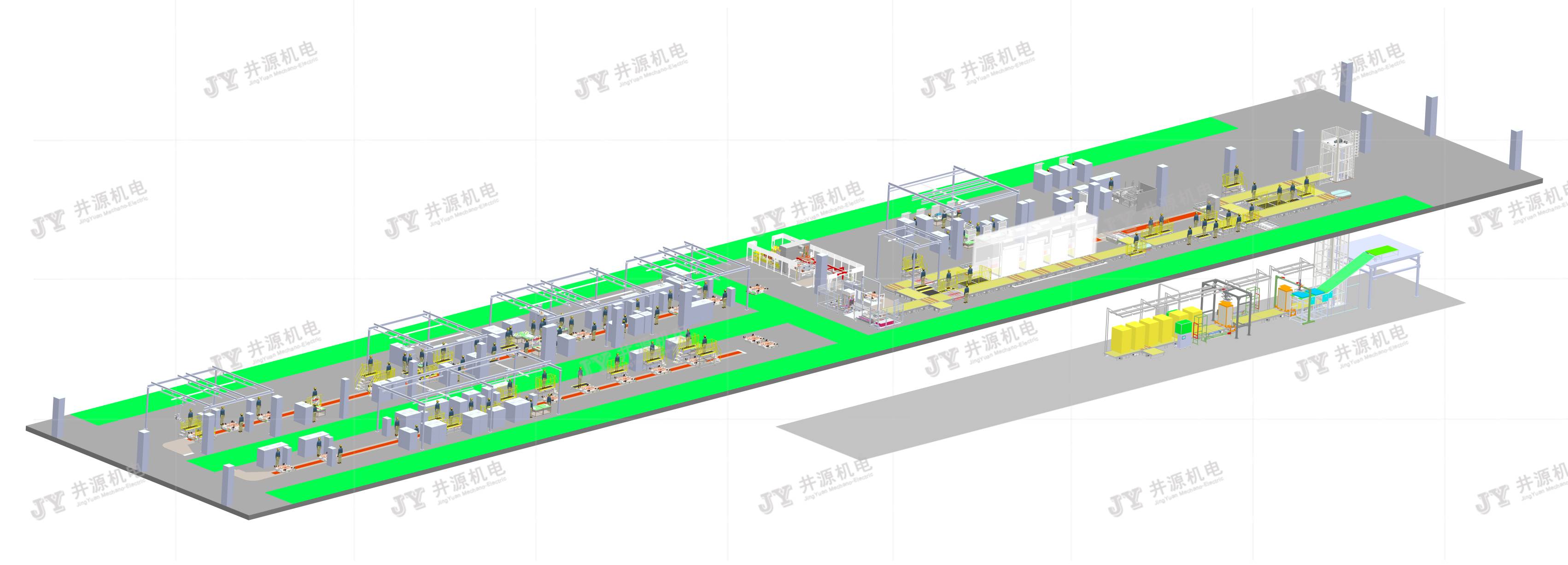

Layout diagram of the final assembly line

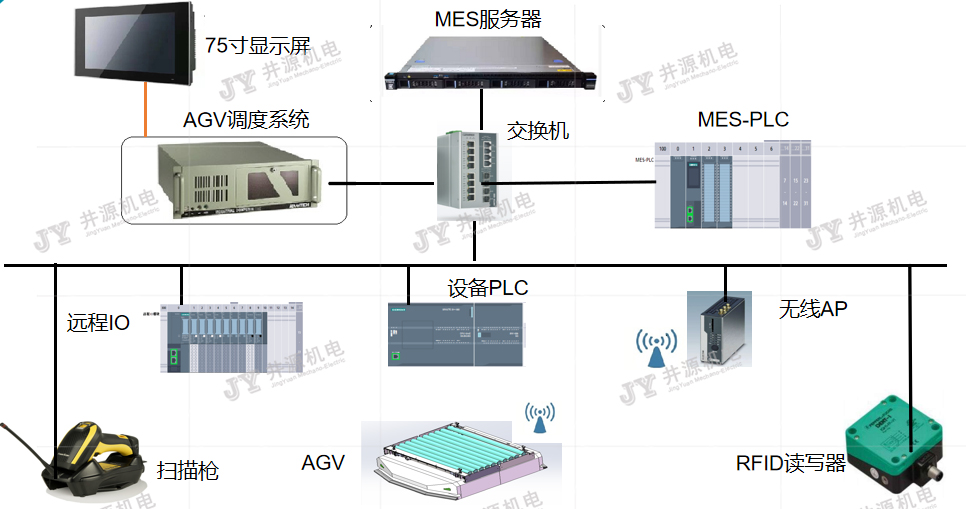

Schematic diagram of communication connections between various specialized aircraft equipment

Project highlights

◆ Assist in the automation and flexible production of Haier's commercial dryer box and component assembly line;

◆ If there is an abnormality in the material or AGV, it can be automatically taken offline for maintenance without affecting the main production line;

◆ The project meets the customer's production capacity requirements and reduces the difficulty of production operations;

◆ Meet the production quality of the product;

◆ Ensure the safety of workers working on the line;

◆ Meet the requirements of mixed production of multiple models.